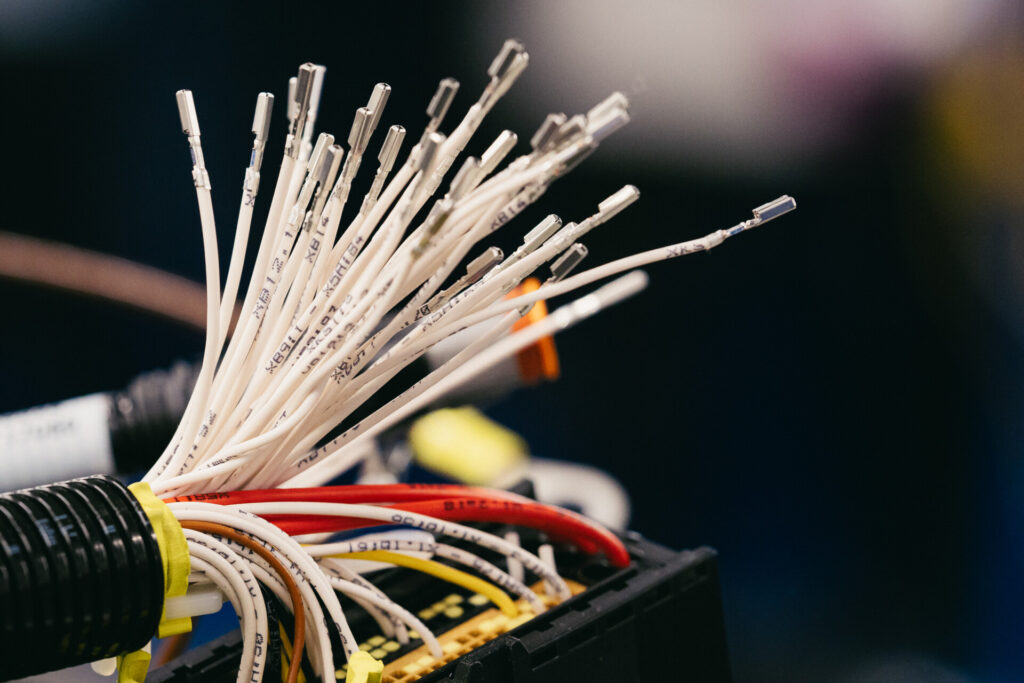

Cable harnesses are the ideal solution for organizing and simplifying complex cabling in machines and systems. We develop and manufacture cable harnesses according to your individual specifications and the highest quality standards.

We manufacture cable harnesses for various industries and applications, including agricultural machinery, construction machinery, medical technology and automotive. Our cable harnesses are robust, durable and meet the highest requirements.

Why steer-by-wire – The future of steering in the off-highway sector Steer-by-wire systems dispense with mechanical or hydraulic connections between…

Safety and comfort in the vehicle In the automotive industry, cable harnesses (in this case called wiring systems) play a…

Wire harnesses are an essential component in numerous technical applications – from the automotive industry and mechanical engineering to medical…

Cable harnesses from rokatec: precision and quality for your electrical systems Cable harnesses are the nervous system of modern electrical…

What is a cable assembly? A cable assembly is a custom-made cable or cable group that is assembled according to…

Our cable harnesses offer you numerous advantages:

Space-saving and clear cabling

Reduced assembly times

Improved ease of maintenance

Greater reliability

Biocompatibility is tested in accordance with ISO 10993. The compatibility of the materials with the human body is examined.

Relevant standards include IEC 61131 (programmable logic controllers) and the EMC Directive 2014/30/EU.

Typically, special cables with high temperature resistance, low weight and good flexibility are used, e.g. PTFE-insulated cables or fluoropolymer-insulated cables.

Relevant standards include ISO 13849 (safety-related parts of control systems) and the EMC Directive 2014/30/EU.

Relevant standards include IEC 60601-1 (general requirements for the safety of medical electrical devices), ISO 13485 (quality management systems for medical devices) and the Medical Device Directive (MDR).

EMC tests are carried out to ensure that the cable harnesses do not cause or are affected by electromagnetic interference.