We are your specialist for customized cable harnesses and assemblies. Our services include the development, design, production and testing of cable harnesses, cable assemblies and assemblies.

Our cable harnesses, cable assemblies and modules are used in a wide variety of industries and applications. Convince yourself of our versatility and our know-how!

Our production takes place at our sites in Emlichheim (Germany) and Coimbra (Portugal). There we use modern machines and testing systems to ensure consistently high quality. Production includes the following steps.

Exact lengths and precise processing for further processing. For this, we rely on the Schleuniger SP36 crimping center, which works with high precision and efficiency. The system enables the fully automatic cutting, stripping and crimping of wires with a processing accuracy of ±0.2 mm. Printing is carried out using inkjet printers from König & Bauer, model Alphajet. These enable printing with black and white ink for optimum marking of the wires.

High-performance stripping machines ensure precise removal of the insulation, while automatic crimping machines press the contacts onto the conductor ends. Our machinery includes state-of-the-art machines from Komax, including the BT-752 and Delta 240 models, as well as machines from the manufacturer KMI, including the 3011 model. We also have many other crimping presses that ensure efficient and precise processing. A particular advantage of our production is the large selection of quick-change tools - we have over 270 different tools at our disposal. These enable us to react flexibly to different cable types and plug connections and guarantee consistently high quality for every assembly. Our machines and tools guarantee a precise crimp connection that meets the highest technical requirements.

For special applications, soldering stations from Ersa and crimping devices from Weidmüller are used to ensure a permanent connection. We also rely on modern ultrasonic welding technology from Schunk Sonosystems. With the Minic II, Minic III and GS50 models, we can produce welded joints with a total diameter of up to 50 mm². These machines enable high-strength and conductive connections that are particularly suitable for demanding applications in automotive and industrial electronics.

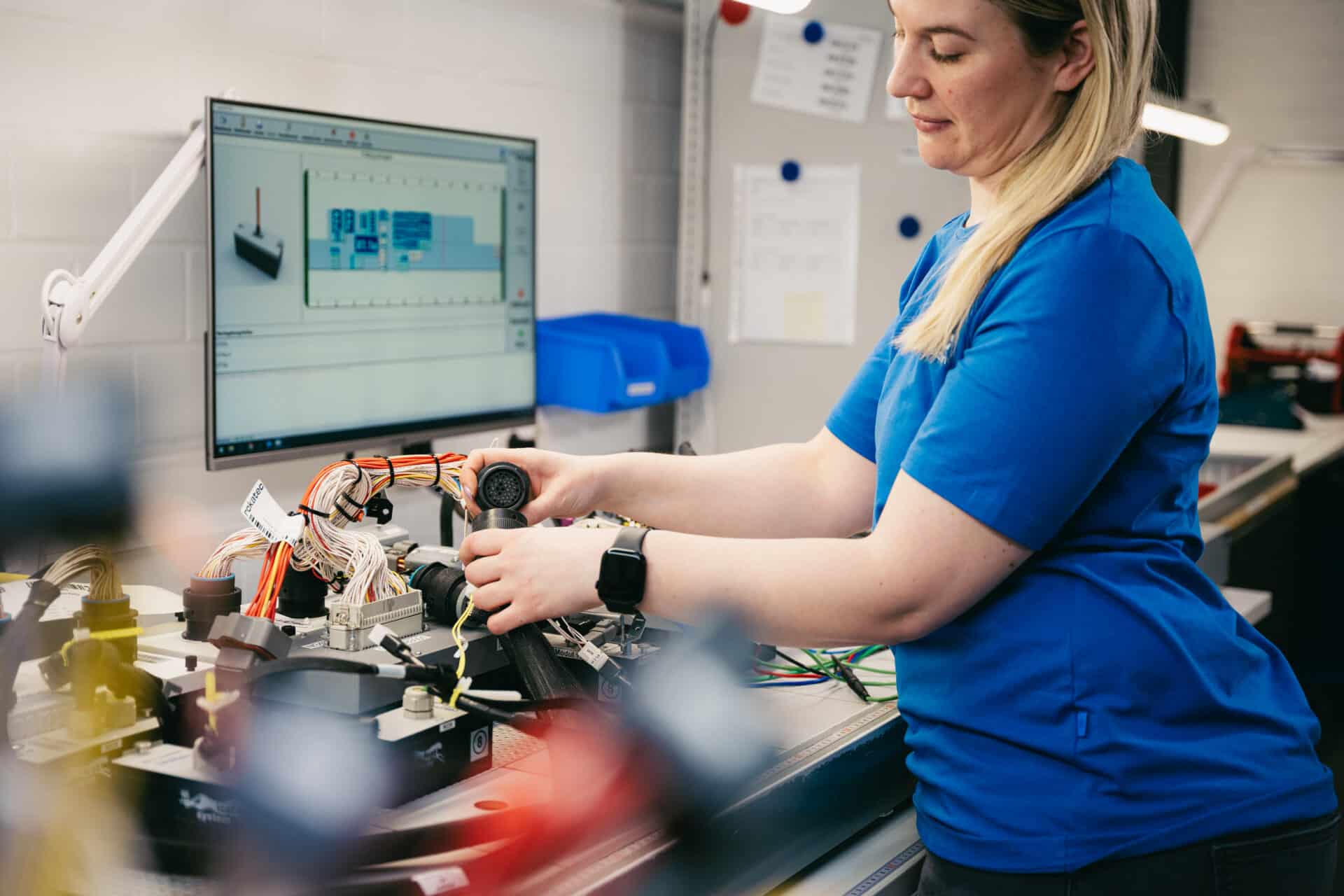

We assemble the connectors completely manually. We use a variety of different connectors from leading manufacturers such as TE Connectivity, Molex, Amphenol, Deutsch, JST, Bosch and Harting. Our range includes circular connectors, flat connectors, multiple connector systems and high-performance connectors specially developed for harsh environments. This diversity enables us to offer the optimum connection solution for every application - be it for vehicle construction, medical technology or industrial control systems.

Various types of corrugated conduits and corrugated hoses from the manufacturers ABB and Delfingen (formerly Schlemmer Kabelschutzsysteme) are used as cable protection. We also process braided sleeves and shrink sleeves in various colors and sizes. The materials are processed using machines from Ulmer GmbH, including the WSM30 and WSM60 models. In addition to these protective measures, we also offer the option of wrapping cable harnesses with special insulating tape. This wrapping / taping technique offers additional stability, flexible installation and can replace bundling with cable ties. We use high-quality adhesive tapes from various manufacturers that are designed for different temperature ranges and mechanical loads.

To ensure the highest quality standards, we rely on the iCat system from Engberts. This modern testing system enables comprehensive electrical testing of our wire harnesses for continuity, insulation and short circuits. The modular test platform offers flexible testing options for a wide range of wire harness configurations and enables complete documentation of the test results.