Wire harnesses are an essential component in numerous technical applications – from the automotive industry and mechanical engineering to medical technology and telecommunications. They bundle and organize electrical cables, ensure reliable power and signal transmission and make a significant contribution to the functionality of complex systems. But there is much more to the production of a cable harness than simply joining wires and plug connections.

Highly skilled manual work in wire harness production

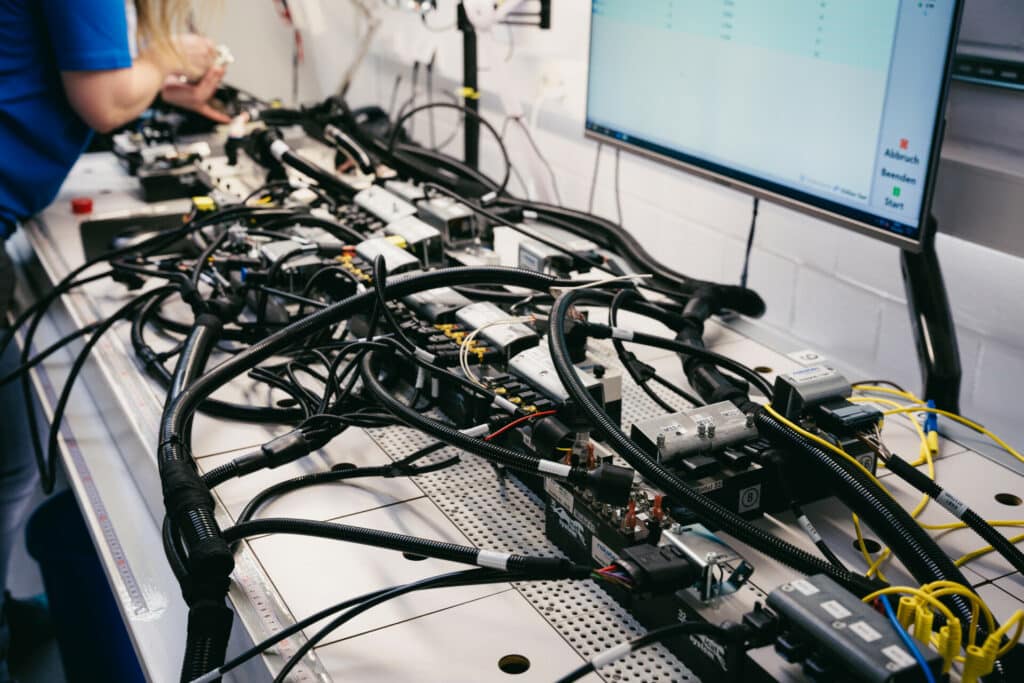

Unlike many other components in industrial applications, up to 80 percent of cable harnesses are manufactured by hand. The reason for this lies in their complexity and individuality: each wiring harness must be tailored specifically to the respective application. While standardized production processes for simple wiring can be automated, individually assembled cable harnesses require qualified specialists.

The manufacturing process begins with detailed planning and a circuit diagram that shows all the connections and technical requirements of the wiring harness. The required cables are then cut to size, stripped and fitted with connectors or soldered connections. Special tools such as crimping pliers or ultrasonic welding devices are used to ensure a secure electrical connection. The individual cables are bundled in further work steps – often using cable ties, hoses or protective braiding.

Challenges and high quality requirements

Quality assurance is a decisive factor in wire harness production. Since a wiring harness can only be repaired with difficulty or at considerable expense after installation, errors in production must be avoided at all costs. A faulty connection or incorrect wiring can have serious consequences – from malfunctions to safety-critical failures. This is why every cable harness undergoes stringent tests, including electrical tests to check conductivity, high-voltage tests and mechanical load tests.

Another quality criterion is the resistance of the cable harness to external influences. Depending on the area of application, cable harnesses have to withstand extreme temperatures, vibrations, moisture or chemical influences. Appropriate materials and protective measures, such as special insulation or sheathing, are therefore already taken into account during the development phase.

Automation vs. manual labor – future prospects

Despite the advancement of automation in the industry, wire harness production remains a discipline that relies heavily on manual labor. The individual customization, the complexity of the components and the high quality requirements make complete automation difficult. Nevertheless, there are advances in robot technology and AI-supported production that can make individual processes more efficient. For example, automated crimping machines or robot-assisted soldering processes enable consistently high quality and faster throughput times.

Conclusion

The manufacture of cable harnesses is a highly specialized craft that requires precision, expertise and the utmost care. The high dependence on manual labor shows that not only technical know-how but also human skill is required here. Quality assurance plays a crucial role, as cable harnesses are difficult or impossible to repair in many applications once they have been installed. Looking to the future, automation technologies will increasingly be used to provide support, but the expertise of skilled workers remains essential in this area.