In cable assembly, reliable crimp connections are essential for a secure electrical and mechanical connection. Various test methods are used to ensure consistently high quality. Here is an overview of the most important methods:

Visual inspection is the first and quickest quality control of crimp connections. It is carried out with the naked eye or with optical aids such as a magnifying glass or microscope.

Test criteria

The mechanical strength of a crimp connection is determined by measuring the pull-out force. The connection is subjected to a defined tensile force in a special testing machine until it is released.

Test procedure:

Objective: To ensure that the crimp is mechanically stable and does not fail under normal load.

Crimp height measurement is a simple and effective method of checking the correct crimping of a crimp.

Test method:

Advantages: Fast and non-destructive testing, ideal for series inspection.

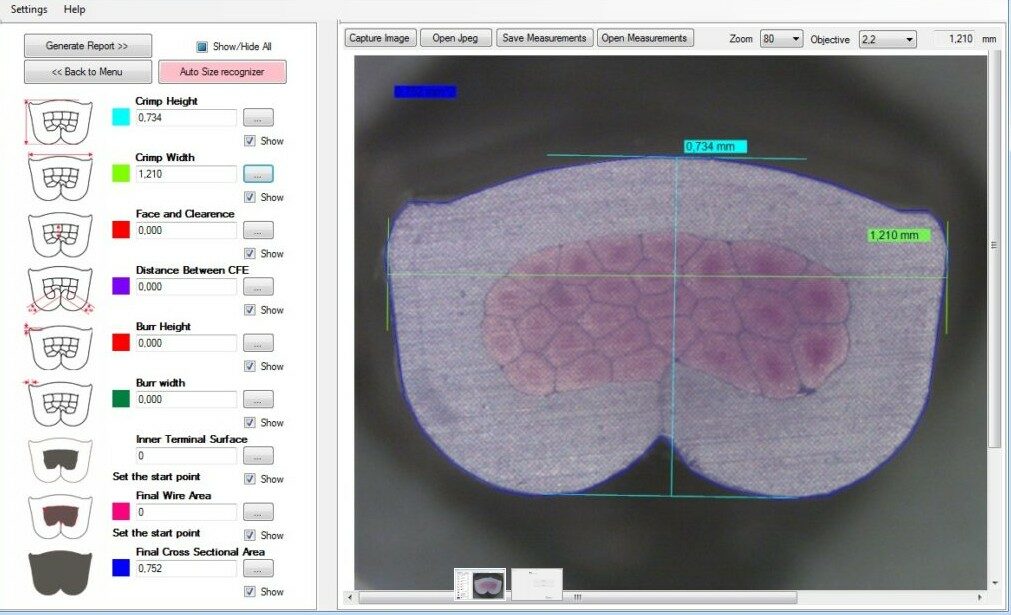

Micrograph analysis is a high-precision method for evaluating the internal structure of a crimp connection. The crimp is prepared and analyzed under a microscope.

Procedure:

This method is particularly important for highly sensitive applications, e.g. in medical technology, aviation or the automotive industry.

The quality of crimp connections can be ensured through the targeted use of these test methods. The combination of visual inspection, mechanical tests and microanalyses enables reliable quality assurance – a decisive factor for durable and safe cable assemblies.