Cable harnesses from rokatec: precision and quality for your electrical systems

Cable harnesses are the nervous system of modern electrical and electronic devices. They ensure the reliable connection of components and guarantee the smooth transmission of power and signals. At rokatec GmbH, we attach great importance to precision, quality and our many years of experience in order to offer our customers customized wiring harness solutions that precisely meet their requirements.

Customized wiring harness solutions for your requirements

We know that no two projects are the same. That is why every order at rokatec begins with a thorough analysis of our customers’ specific requirements. We work closely together to develop optimal solutions that are perfectly tailored to the respective requirements. We take into account important factors such as

- Ambient conditions (e.g. temperature, humidity)

- Mechanical loads (e.g. vibrations, tensile forces)

- Electrical properties (e.g. current, voltage)

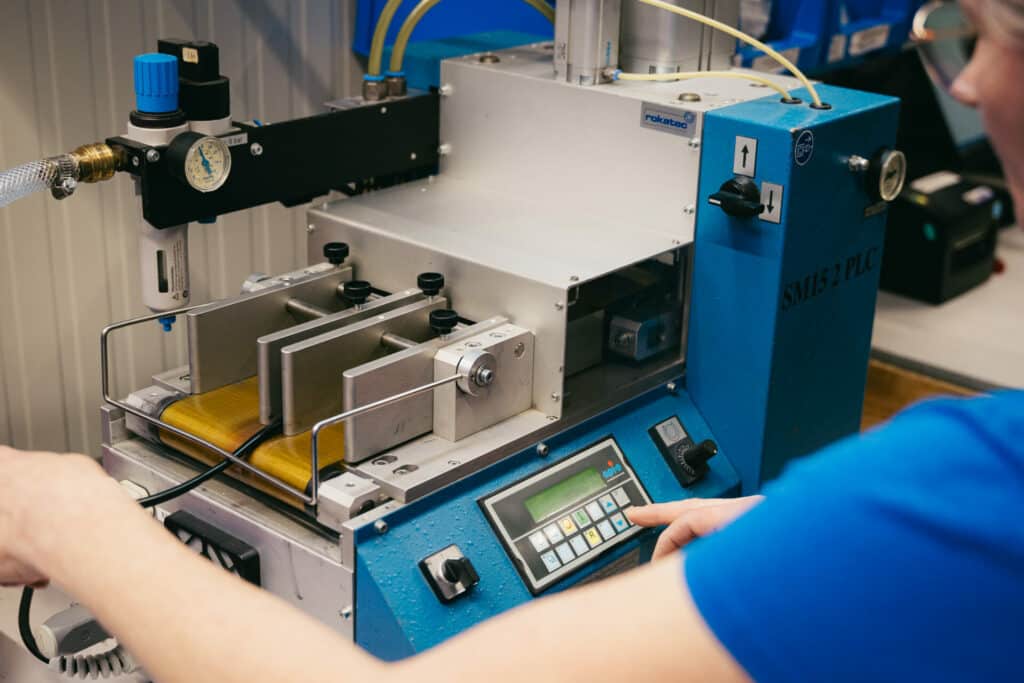

Precise production thanks to modern technology

Our wire harness production takes place at our sites in Emlichheim (Germany) and Coimbra (Portugal). We use state-of-the-art machines and testing systems to ensure consistently high quality.

Cable processing at the highest level

The production of cable harnesses involves several precise steps:

- Cable cutting and printing: We ensure exact lengths and precise processing. Among other things, we use the SP36 crimping center from Schleuniger, which cuts, strips and crimps fully automatically – with an accuracy of ±0.2 mm. To mark the wires, we use inkjet printers from König & Bauer (Alphajet model), which can use both black and white ink.

- Stripping and crimping: high-performance stripping machines remove the insulation precisely, while automatic crimping machines press the contacts securely onto the conductor ends. Our machinery includes state-of-the-art equipment from Komax (e.g. BT-752 and Delta 240) and KMI (e.g. model 3011) as well as a variety of other crimping presses. Our flexibility is guaranteed by a large selection of quick-change tools (over 270 different ones), which enable us to react quickly to different cable types and plug connections.

- Soldering, crimping and ultrasonic welding: For special applications, we use soldering stations from Ersa and crimping devices from Weidmüller to create permanent connections. In addition, we rely on ultrasonic welding technology from Schunk Sonosystems (Minic II, Minic III and GS50 models) to create high-strength and conductive connections with a total diameter of up to 50 mm² – ideal for demanding applications in automotive and industrial electronics.

- Assembly of the plug connections: We assemble the plug connections carefully by hand. We process a wide range of connectors from leading manufacturers such as TE Connectivity, Molex, Amphenol, Deutsch, JST, Bosch and Harting. Our range includes circular connectors, flat connectors, multiple connector systems and high-performance connectors for harsh environments.

Protection and quality assurance

- Sheathing and protection: To protect the cable harnesses, we use various corrugated tubes and conduits from ABB and Delfingen (formerly Schlemmer Kabelschutzsysteme) as well as braided sleeves and shrink sleeves in various colors and sizes. The materials are processed using machines from Ulmer GmbH (e.g. WSM30 and WSM60). We also offer the option of wrapping cable harnesses with special insulating tape (taping technique) to ensure additional stability and flexible installation.

- Electrical testing: To ensure the highest quality standards, we use the iCat system from Engberts. This modern testing system enables comprehensive electrical testing of our cable harnesses for continuity, insulation and short circuits. The modular test platform offers flexible test options and complete documentation of the test results.

At rokatec, we pride ourselves on providing our customers with high-quality wire harness solutions that impress with their precision, quality and reliability.